This South Dakota Family Knows What They Need To Remain Viable

By: Corinne Patterson

Monday mornings at 6:30 sharp, four ag businessmen near Ideal, South Dakota, gather to discuss a simple acre of ground.

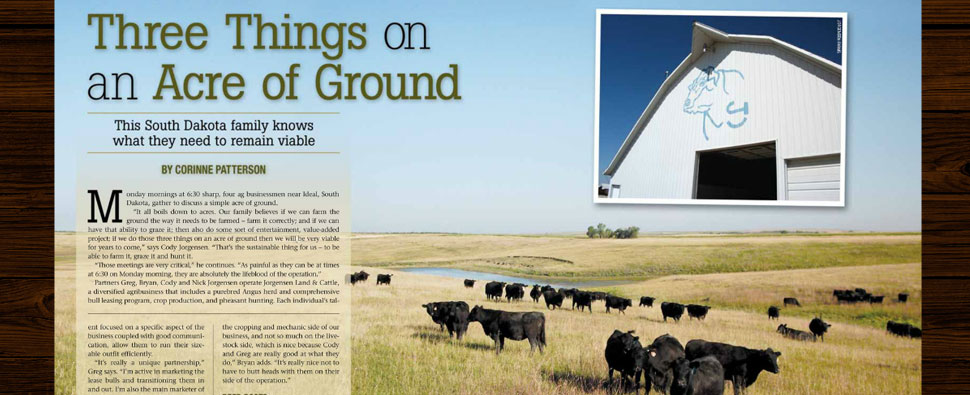

“It all boils down to acres. Our family believes if we can farm the ground the way it needs to be farmed – farm it correctly; and if we can have that ability to graze it; then also do some sort of entertainment, value-added project; if we do those three things on an acre of ground then we will be very viable for years to come,” says Cody Jorgensen. “That’s the sustainable thing for us – to be able to farm it, graze it and hunt it.

“Those meetings are very critical,” he continues. “As painful as they can be at times at 6:30 on Monday morning, they are absolutely the lifeblood of the operation.” Partners Greg, Bryan, Cody and Nick Jorgensen operate Jorgensen Land & Cattle, a diversified agribusiness that includes a purebred Angus herd and comprehensive bull leasing program, crop production, and pheasant hunting. Each individual’s talent focused on a specific aspect of the business coupled with good communication, allow them to run their sizeable outfit efficiently.

“It’s really a unique partnership,” Greg says. “I’m active in marketing the lease bulls and transitioning them in and out. I’m also the main marketer of the 30-month old bulls.”

Greg’s son Cody oversees the genetics of the cattle and the details that go into managing the bulls that call the ranch home for part of the year.

“He’s heavily involved in the marketing of the purebred side, which I’ve really walked away from because I’m having so much fun with the leasing thing,” Greg shares. Cody is extremely involved in the pheasant hunting part of our business, too.”

Greg’s younger brother Bryan manages the operation’s farming activities and shares hunting responsibilities with Cody.

“My passions have always been on the cropping and mechanic side of our business, and not so much on the livestock side, which is nice because Cody and Greg are really good at what they do,” Bryan adds. “It’s really nice not to have to butt heads with them on their side of the operation.”

DEEP ROOTS

Greg and Bryan’s granddad, Martin Jorgensen, Sr. and his wife, Gertrude, selected the fertile, open plains of South Dakota for their homestead in 1909 as immigrants from Denmark.

Their father, Martin, Jr. and Uncle Don managed and grew the operation during the 1940s through the 1960s with a pioneering spirit in crop production and a purebred Angus herd. With a fresh 1974 college diploma in hand, Greg jumped at the opportunity to join the family business.

“When I came home from college, Uncle Don was kind of ready to slow up and that was the process that allowed me to buy his share out and become a partner with my dad,” Greg recalls. Both Greg and his dad Martin Jr. share a passion for the cattle industry. Martin was an early adopter, and some would argue, pioneer, of the performance testing movement that began in the late 1960s.

“When Dad built that program, he, like so many others who jumped into the purebred industry, looked at the situation and saw that everybody was doing the same thing,” Greg recalls. In search of an opportunity to improve, differentiate and provide improved genetics, Martin recognized the advantages of genetically selecting cattle based on performance. Martin took advantage of the knowledge from various areas of beef production by building relationships with geneticists, marketing experts and various other specialists.

“We have a line-bred program,” Greg says. “We occasionally step out and use an outcross bull, but we’re very careful when we do it. We don’t want to end up with other issues that sometimes come with outside genetics. We haven’t deviated from that program that Dad put together back in the 1960s.”

Cody is quick to point out that he’s fortunate to leverage the years of experience both Martin and Greg offer.

“That’s really my main job, to study and be disciplined with this cow herd,” Cody says. “I have had the great honor to follow my dad and grandfather in terms of making all the decisions in selection and matings of the cows. I’ve studied what my grandfather did in the ‘50s, ‘60s and ‘70s, and then I have also studied the way my dad did it in the ‘80s and ‘90s. I have the tools to go back and understand what worked and what didn’t work.

With computers and the Internet I have been able to study these pedigrees, and that was a huge advantage.” Cody, in true family style, is also not afraid to be an early adopter of upcoming technology and ideas. He now utilizes DNA gene marker selection to better identify their top cattle.

“The American Angus Association has been very good at helping us identify traits that work and traits that don’t work,” he adds. “There’s so much information that we have access to today that years ago we didn’t have.”

Every registered Jorgensen cow has her Zoetis High Density 50K (HD 50K) DNA profile. This test provides genomic-enhanced expected progeny differences (GE-EPDs) and indexes for 14 traits.

“Along with all the quantitative genetic research we’ve done in the past and currently, we now throw DNA on top of that. It certainly can help us make some good decisions with the cow herd in the future,” Cody says.

“That is very critical for us to maintain that integrity of being on the forefront of performance testing and on the forefront of identifying cattle that are above average.”

NO BULL

Reflecting on the beginning of their bull leasing program, Greg acknowledges that the system was born out of the agricultural economy’s condition at the time.

“In the 1980s commodity prices were really low, and it was tough to scratch out a living in agriculture. It was really out of necessity that we started leasing out the bulls. People couldn’t afford to own a bull, but they needed one and we had extras available.

That’s how it got started,” Greg says. Today, the father-son team place nearly 3,500 bulls into commercial programs across the nation. Greg and Cody rely heavily on referrals and word-of-mouth to place their bulls.

“That business over the years took on a pace of its own. For years we didn’t advertise it. A neighbor would tell his neighbor about it, and pretty soon we might send five or six bulls 100 miles away to a ranch. The next year there might be 20 bulls in that area. It just blossomed that way.”

Service is a key component in a seedstock supply business, and the Jorgensens feel their bull leasing program

is an extension of their service.

“The customer needs a bull, but he doesn’t like to deal with the bulls in the off-season so that service becomes ours. We take care of the bulls in the off-season,” Greg says. “When those producers really study their costs and analyze everything that’s related to the purchase of a bull and bull ownership, they quickly realize that economically it makes a lot of sense to lease bulls. It’s become service, service, service, and as long as we stay competitive in price, it will grow. Our lease program usually stays within a 200-mile radius of our ranch, however we have customers as far away as 800 miles”

After the first breeding season, yearling bulls are gathered and returned to the Jorgensen’s bull development center where they undergo a culling and feeding process Greg calls “reconditioning.”

“Obviously if there are any injuries, those bulls exit the program. We’ll get some condition on the bulls and get them back up to around 1,300 to 1,350 pounds in our feedlot,” he notes.

“Then, we’ll turn the bulls out to forage on grazing cane, corn stalks, and other available forage for several months to keep our costs down. They’re brought back into the facility in March as nearing two year-olds, and we get them back in condition. At this point in time, the bulls are ready for their second breeding season and lease.”

Herd health is one of the most important components to the lease program.

“Our veterinarian, Dr. John Voegeli at the Winner Animal Clinic, guided us through our leasing project,” Cody says. “At first it was very difficult to talk a vet into allowing us to sell a used bull. That’s a big no-no for veterinarians. Every vet you talk to will say ‘don’t ever buy or lease a used bull’. That was a hurdle for us.”

The Jorgensens worked with Dr. Voegeli to develop a comprehensive health protocol process including Trichomoniasis testing each bull prior to a non-virgin breeding season. This partnership has helped ensure that their management protocols offer disease free bulls. They have conducted more than 40,000 non-virgin trich tests processed to date without a single positive case.

When the two year-old bulls return to Jorgensen’s bull development center they are prepared for their final exit out of the program. These bulls immediately start their recondition program, are trich tested, and then sold as 30-month-old bulls.

“Most of those 30-month-old bulls go to the southern states, particularly Florida. That particular environment in Florida and the southern states really benefits from these 30-month-old bulls because they’re essentially done growing and they can hold their own in that particular environment,” Greg says. “We can be very price competitive because we already have the two leases on the bull.”

The Jorgensens work with 13 cooperator herds to fulfill the bull orders. These herds have been using Jorgensen genetics for 40 years or more and have what Greg considers like-kind genetics.

“For many years, we’ve had very loyal customers that come to our sale and purchase bulls,” Greg says. “We started with one of our oldest customers. We had used them previously as a test herd back when you had to have an actual progeny test with live terminal cattle in order to get carcass information. We were buying his steers, and now we buy his bull calves.”

These herds have capitalized from the Jorgensen’s strict line-breed genetics from what Cody refers to as the parent-stock cow herd. These partner herds select their genetics from the Jorgensen’s annual bull sale the third Monday in April, from an offering of 150 registered Angus bulls.

When the Jorgensens buy bull calves from their cooperating herds,

detailed requirements are attached to the price tag. Birth weights and sire groups are imperative, and the partners have synchronized health regimens prior to bull calf delivery. Calves in January and February receive an electronic ID tag upon arrival and are cross referenced to their ranch number and ranch information. Then, bulls are freeze branded based on birth weights.

“For example, we get 100 head of calves from a ranch. The lightest birth weight calf would have a freeze brand ending in ’00,’ indicating he had the lowest birth weight in his contemporary group. The next lightest calf would be ‘01’, and so on. We’ve learned that our customers, almost without exception, have some kind of a birth weight in mind when they lease bulls. That’s why we rank the bulls in numeric order based on their birth weight.”

While in the development process, bulls are culled constantly. Employees have the right to cull a bull if he shows a disposition problem while handled. Bulls have to meet performance standards and pass a breeding soundness exam (BSE) before their first lease. Greg says the cull rate reaches 20 percent.

Cody knows his role in selecting genetics for the parent-stock registered cow herd influences hundreds of thousands of cattle down the line, so he is disciplined in culling decisions as well. The Jorgensens have been utilizing embryo transfer in their herd since the late 1970s. Only cows that have proven, high indexing calves for at least three years are selected as donors. Ten cows that meet these standards annually are taken out of production and flushed for one year, and 300 embryos are implanted the following year.

Bulls are leased depending on individual ranch need. Some ranches have a narrow breeding season of 30 days, with the vast majority keeping bulls for around 100 days.

Delivery coordination is an intricate process, Greg says. “We try to make the best arrangements we can to get them delivered as close to, or right to the ranch, if possible.”

THE NEED FOR FEED

For Bryan, providing hungry, growing bulls the right kind of feedstuffs while maintaining the quality of his farm ground and a place for wild game to thrive is a delicate balance. His key management practice has been 100 percent no-till farming on nearly 11,000 acres since the early 1990s.

“We have a very diverse location with a lot of different crops. We have spring grain such as oats and spring wheat and then we go to winter wheat. Then we have corn, milo, cane, soybeans, alfalfa, peas, millets and other crops,” Bryan says. “The biggest thing I like about what we do is having the livestock in the system, which gives me a lot of opportunity to grow not only feed grains, but forages as well. It really allows me a lot of dimension within our locations, whereas if I were just a grain farmer I would not have those opportunities. I design rotations based around the needs of the cattle.”

Bryan is passionate about the health of the soil on the ranch and has done his level best to ensure it is a thriving environment.

“For the last 10 to 15 years, I’ve focused on nutrient efficiency much like Cody and Greg have focused on feed efficiency with the cattle. My goal is to try to get a lot more efficiency out of the soils and try to minimize the amount of nutrient input,” Bryan says. “We’ve done that by no-till, increasing organic matter in the soil and improving the biological aspect of the soil by getting more biological growth out of our soil. We’re trying to return it to more of a native state similar to what you would find in a native prairie soil system.

“We discovered that the efficiency of the soil improves so much that you can cut your nutrient demands in regards to applied nutrients by as much as 50 percent to 60 percent compared to what we used to do,” he adds. “At the same time your soils are healthier and your plants are healthier. There are a lot of things that fall into place so it’s really a cool thing to see the soil improve.”

Whether their individual interest is in the cattle or land, each Jorgensen works to balance what grazing advantage the bovine creature brings to the South Dakota plains.

“Ultimately what we’re trying to do, in my mind, is create a long-term sustainable system to help build that soil for the next generation,” Bryan says.

“We strive to do it economically and still provide the feedstuffs that we need and the cover for the wild game for the hunting that we do. It’s all part of the system.”

FOR THE BIRDS

The harmonious relationship between the bovine and soil strikes another cord in the Jorgensen’s threefacet approach.

The harmonious relationship between the bovine and soil strikes another cord in the Jorgensen’s threefacet approach.

“We are blessed to have wild pheasants on our property. We decided it was a great business to add – the entertainment side of the production agriculture,” Cody says.

With no-till farming and livestock grazing management practices, the Jorgensen property is a haven for wild pheasants. Plenty of cover and feed is a byproduct of the grazing and farming practices that create a natural conservation aspect of their operation.

The Jorgensens built a full-service lodge two years ago. They moved from day hunts to a complete package offering 4-night, 3-day hunts including meals and lodging starting the third Saturday in October through the end of the year.

“It certainly ties right into where we live and what we do,” Cody says. “The family enjoys it, and we enjoy entertaining people. It really is a nice fit for us.” Even with thousands of acres to evaluate at their Monday morning meeting, the Jorgensen family doesn’t deviate far from considering what they can do with just one acre.

“Our big goal as a family is to pass the operation on to the next generation,” Bryan says. “Equity transfer is very important to us. If we can make something that’s transferrable such as the land assets or land resources better for the next generation, that’s really the ultimate goal.”